| ØRKILD FOUNDRY Foundry since 1831 |

| Special Jobs: The repair of keels damaged by bottom contact or otherwise. Reduction of boat depth trough shortening of lead keels and compensatively adding weight building wings or weights, on to the keel. ØRKILD can cut up lead keels, but not iron keels. See samples of adding weight to lead or iron keels building on wings or weights, and how to handle it. Adding weight down to keel moves the total centre of gravity downwards See how to build your very own keel, and other very special jobs made by ØRKILD |

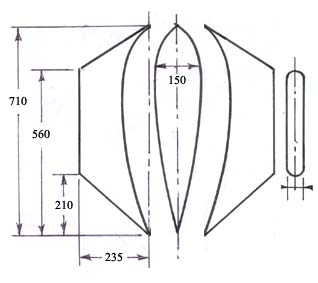

| Different options for the increase of weight and addition of wing profiles |

|

Type |

Vægt |

Model |

|

|

A |

Bolted-on bulb |

135 kg. |

Mosquito-85 |

|

B |

Built-on wings |

2 x 175 kg. |

Red |

|

C |

Built-on wings |

2 x 240 kg. |

Green |

|

D |

Bolted-on weights |

2 x 250 kg. |

Phantom - 42 |

|

E |

Built-on wings |

2 x ??? kg. |

Yellow |

|

F |

Built-on wings |

2 x 75 kg. |

Blue (used on Granada 27) |

|

G |

Bolted-on weights |

2 x 1011 kg. |

Custom plug |

|

Bolted-on weights |

2 x ?? kg. |

Your boat |

|

A: |

Before |

Bulb |

After |

|

Mosqoito-85 This bulb is especially made for the Mosquito - 85 to add weight to her cast iron keel. Lift the boat, push lead part inn under, lower the boat, drill through keel or make thread holes and fasten the bulb with bolts. |

|

|

|

|

|

|

|

|

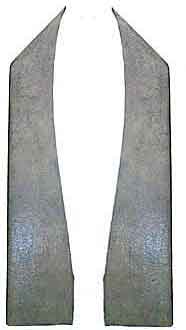

| B: Redwing | To be mounted on keel so that outside edges of wings are parallel to keel midline. Profile is not symmetrically but has biggest curve on lower side. Wings are delivered with 4 holes for bolts. |

D: Phantom-42 |

Additional weights made to fit keel on Phantom - 42. Weights are delivered with 5 boltholes. |

|

|

|

|

| C: Greenwing | To be mounted on keel so that outside edges of wings are parallel to keel midline. Profile is not symmetrically but has biggest curve on lower side. Wings are delivered with 4 holes for bolts. |

E: Wyellowing | To be mounted on keel so that outside edges of wings are parallel to Keel midline. Profile is symmetrically. Wings are delivered with 4 holes for bolts. |

|

|

|

|

|

|

||

| More weight in your keel? How? Wings and weights shown in above lines, A -G, can be delivered made of lead,with fixed holes going countersunk access for nuts and sheaves. Measurements above in mm. and kilos. are given approx. |

Position on keel |

Keel frame templet |

|

|

Bolts: For mounting can be delivered as to individual measurements |

|

|

|

|

Clinching cliff on the bottom a 34 ft. boat lost one side of her keel wings. Ørkild has made a symmetrically wing plug, made a mould around this plug and poured a new wing melted together with the old keel. To eliminate any risk boat wings are furthermore secured through bolts going through. |

|

|

|

|

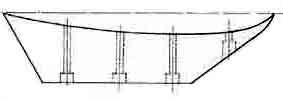

Build your very own keel. The following 12 pictures shows how to build your own keel design. |

| Make the plug for your bulb after a design, which you can buy, or according to drawings. Use wood, or foam of a quality weighing > 40 kilos. A-per cubic meter, and add 3 layers of GRP to keep it together during the moulding process. ØRKILD, can make your lead bulb through, holes for safety bolts. |

|

|

|

|

|

|

|

|

|

|

|

|

1-2-3. For the flange up under the boat you need a steel plate, in the shown sample a 22 mm. plate, cut after a template made on top of the existing keel or from the bottom of your boat. Drill the holes for bolts and safety bolts and weld, as shown, bolts onto the underside of the plate. At this stage you also decide the distance between plateoon top of keel and the steel flange plate and you cut and weld the strength elements for the body together with top plate. In the shown sample steel square profile tubes 80x80x5 mm.are used. |

4-5-6..Turn flanges to right position and place it onto the keel top plate. Be sure it is exact in position and then weld the strength |

|

|

| www.oerkild.com mail@oerkild.com |

Støberiet Ørkild Bodøvej 11 DK - 5700 Svendborg |

Tlf.: + 45 62 22 02 84 Fax: + 45 62 22 02 83 Privat: + 45 62 22 97 58 |